2”, Air-bearing spindle, DC-brushless, rotate up to 60krpm.

Compatible with 2”- 3” hub and annular blades. Covering up to 8” round products.

Optimized for variety of products such as:

• Silicon wafers

• Thin-film devices

• High-brightness LED packages

• SAW filters

• Glass wafers, IR filters

• PZT transducers

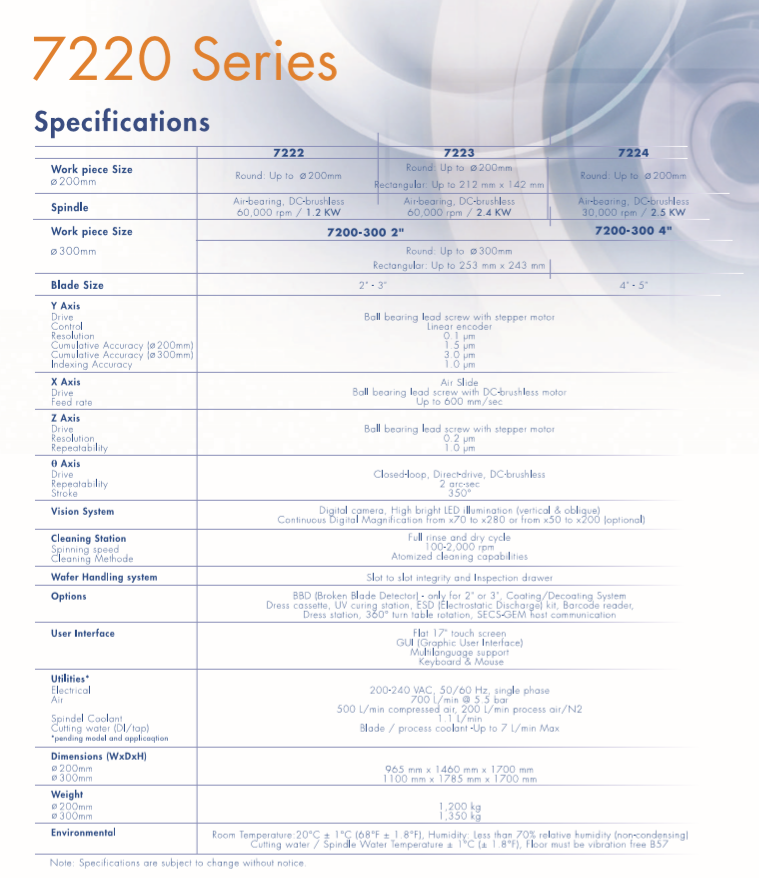

System Specifications

Work piece size: Up to ∅ 200 mm or ∅ 300 mm

Blade size: 2"-3"

Spindle: Air bearing, DC-brushless 60 krpm, 2.4 kW

Indexing Axis (Y)

Drive: Ball bearing lead screw with stepper motor

Control: linear encoder

Resolution: 0.1 µm

Cumulative accuracy (∅200): 1.5 µm

Cumulative accuracy (∅300): 3 µm

Indexing accuracy: 1.0 µm

Feed Axis (x)

Drive: Ball bearing lead screw with DC-brushless motor

Feed rate: up to 600 mm/sec

Cut Depth Axis (z)

Drive: Ball bearing lead screw with DC-brushless motor

Resolution: 0.2 µm

Repeatability: 1.0 µm

Rotary Axis (θ)

Drive: closed-loop, direct-drive, DC-brushless

Resolution: 4 arc-sec

Stroke: 350 deg.

Vision System

Digital camera

High bright LED illumination (vertical & oblique)

Continuous digital magnification: from x 70 to x 280 or from 50 to x 200 (optional)

Cleaning Station

Full rinse and dry cycle

Spinning speed: 100-2,000 RPM

Cleaning method: Atomizing capabilities

Wafer Handling System

Slot to slot integrity and Inspection drawer

Options

BBD (Broken Blade Detector)

UV curing station

ESD (Electrostatic Discharge) kit

Barcode reader

Dress station

350° turn table rotation

SECS-GEM host communication (optional)

User Interface

Flat 17" touch screen

New User Interface (NUI)

Multilanguage support

Keyboard & mouse

Utilities

Electrical: 200-240 VAC 50/60 Hz, Single phase

Air/N2: 700 L/min @ 5.5 bar

500 L/min compressed air, 200 L/min process air/ N2

Spindle coolant: 1.1 L/min

Cutting Water (DI/tap): Blade/process coolant - up to 7 L/min

Dimensions (WXDXH):

∅200: 965 x 1,460 x 1,700 mm

Weight ∅200: 1,200 kg

7220 Series Bochure.pdf

7220 Series Bochure.pdf