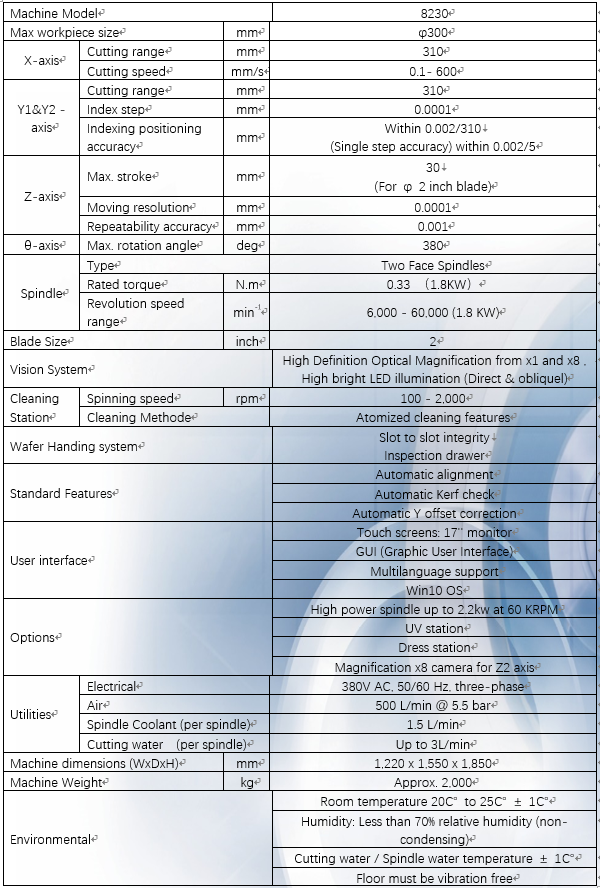

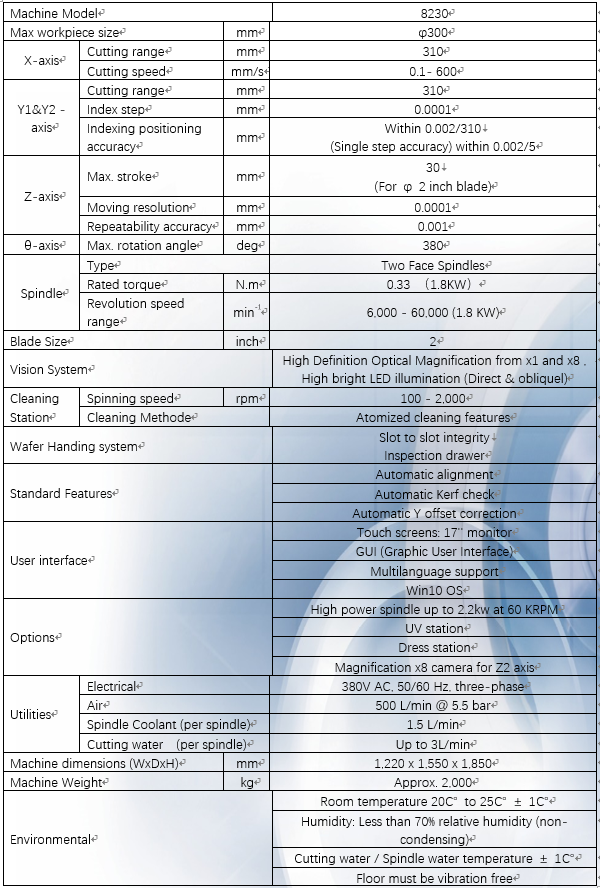

The ADT 8230 is a high-efficiency, high-precision, high-performance and low-cost fully automatic twin-spindle dicing machine with up to 12 inches maximum workpiece size.

Features and Benefits

• Flexibility - Supports Hub and Hubless blades up to 3".O.D

• Spindles of 1.8 kW or 2.2 kW high power

(forchallenging applications)

• Intuitive operation interface using a large 17" touch screen monitor

Leading Applications

• Silicon wafers discrete devices

• Silicon carbide(SiC)

• MEMS

• SAW devices

• Glass wafer

• Packaging(QFN, LED...)

Ease of Use

The 8230 operates with the ADT intuitive New graphic User Interface (GUI), and the monitor screen is a 17" touch-screens with better flexibility and visual effects.

Other Key Features of Importance

• Highest Dicing Process Speeds - Lowest Cost

• Air spindle

• Fast automatic alignment and cut positioning for increased throughput

• Automatic Kerf check and quality analysis for maximum precision

• Process data logging and statistical analysis

• Fast & Simple Blade Change with a locking spindle shaft

• SECS / GEM platform ready

• Full access to any area of the system for easy maintenance access

8230.pdf

8230.pdf