ADT’s New Product 8230,

12” Fully Automatic Twin-Spindle

Dicing Machine

On October 29th, Advanced Dicing Technologies Co., Ltd. (Zhengzhou) held

its latest product launch in Hefei, at which it showed the 12-inch fully

automatic twin-spindle dicing machine crafted by ADT's R&D team in China,

ADT's R&D team in Israel and LP's R&D team in the UK. At the same time,

ADT also presented a series of wafer and packaging module to meet the needs of

users in the semiconductor industry.

Mr. JESSE PARKER, Vice President of ADT, introduced the company's

expansion in the international and domestic markets, and gave a brief

introduction to the new products. Then, Mr. Zhao Tongyu, Chairman of Advanced

Dicing Technologies Co., Ltd. (Zhengzhou) made a speech, he mentioned that in

the past two years, the whole domestic semiconductor industry has been facing

unprecedented pressure. No matter from the user’s demand or market challenges,

everyone in the industry needs to make self-change and upgrade of products to

achieve breakthrough results. This is precisely the pursuit of Advanced Dicing

Technologies Co., Ltd. (Zhengzhou) and its subsidiaries, to continue to provide

the market and its customers with solutions of efficient, reliable and easy

operating high-end dicing machine.

As a Chinese company, Advanced Microelectronics Equipment (Zhengzhou)

Co., Ltd. was jointly funded by the Henan Government, Zhengzhou Government,

listed company GL Technology and funds affiliated to the Institute of the

Chinese Academy of Sciences at the early stage of its establishment, in an

effort to build a leading role high-tech enterprises with capability of research

and development, production and sales of high-end equipment in semiconductor

packaging and testing industry. In October 2019, the company wholly acquired

the world's third dicing machine vendor - Israel Advanced Dicing Technologies

(ADT). After the acquisition was completed, the company invested in innovation

and research and development while integrating multiple technologies, and

developed a 12-inch fully automatic twin-spindle dicing machine, achieved localization

of the production, technical solutions and after-sales service for wafer and

package dicing.

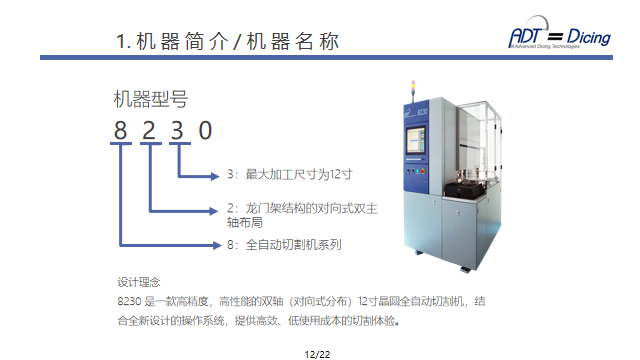

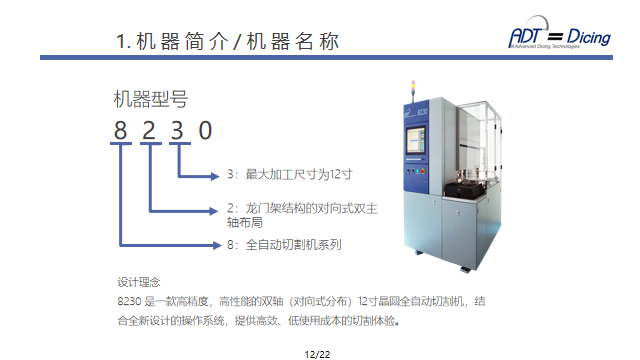

The ADT 8230 is a fully automatic twin-spindle dicing machine with high

efficiency, high precision, high performance and low cost of use. The 8230

series uses a newly developed graphical user interface (GUI) with a 17"

touch screen display for greater flexibility and visual impact. The speed of

equipped air spindle reached 60,000rpm/1.8kW and equipped with lockable spindle

when changing blades. This machine is quicker and easier to operate, and

realizes the full automation of wafer handling, alignment and dicing. At the same time, the

machine can adjust itself based on the automatic kerf mark inspection function

to optimize dicing quality. The machine can record the dicing process

information, analyze the use of blade, the equipment production data, the

operator production data, the equipment production efficiency and personnel

performance and greatly improve the user's production management efficiency and

accuracy.

ADT 8230 has equipped with a 17-inch

touch screen, which can monitor the operation status of the machine during the

dicing process; and with drop-down type multi-information display interface,

which can show the status of the machine at a glance. The followed keyboard

design makes it more efficient to edit data. The local magnifying glass

function helps to improve the alignment accuracy. Meanwhile, the user interface

can be customized according to the user's needs. Modular design of both

hardware and software with higher power air spindle, UV system, forced exhaust,

deionization exhaust, unlimited rotation of the table and it is easy to add

online functions.

As one of the world's top three suppliers of dicing systems, ADT's dicing

equipment is at world leading level in dicing accuracy, efficiency and quality.

Its equipment is widely used in LED packaging, LED gallium arsenide wafers,

discrete device wafers, passive devices, microelectronic sensors, wafer-level

camera modules, image sensors, camera lenses, infrared filters, optical fibers,

radio frequency communications industry. Its customers include Huawei, TE,

Epson, Diodes, JCET and other more than 60 world-known enterprises.

After the acquisition, Advanced Dicing Technologies Co., Ltd. (Zhengzhou)

specializes in ADT dicing machine, dicing blades and dicing peripherals. The sales

center is located in Pudong, Shanghai, with global sales and after-sales

service in the U.S. (Arizona and Pennsylvania), Taiwan, the Philippines, Europe

(U.K.) and Israel. They have a 500 square meters class 1,000 clean room with a

full set of equipment in Suzhou as an application lab and customer training

base. In addition to the technical service team in Shanghai, ADT also has

service team and engineers in Suzhou, Tianjin, Chengdu, Shenzhen, etc., which

can provide in time technical services to customers in mainland China. In the

future, the company will integrate international technical resources, as well

as innovative research and development capabilities, and strive to realize the

domestic replacement of high-end semiconductor dicing systems in China to catch

the opportunities and challenges of the semiconductor industry.

ADT said, at this stage a number of ADT 8230 has been in some well-known

domestic semiconductor packaging and testing enterprises in China for

production trial and evaluation, and already won some praise from these users.